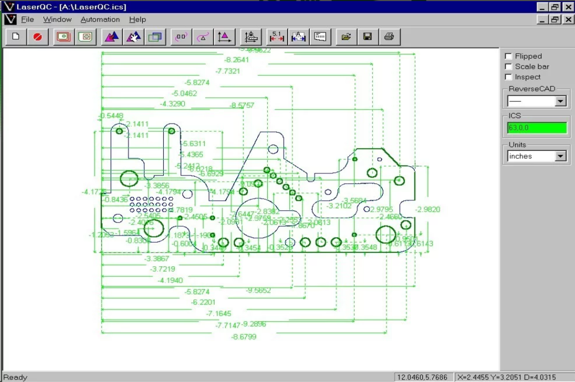

Система вимірювання Virtek LaserQC

Про послугу:

Використання ручних вимірювальних інструментів для контролю якості деталей з листового металу — один із найтрудомісткіших процесів.

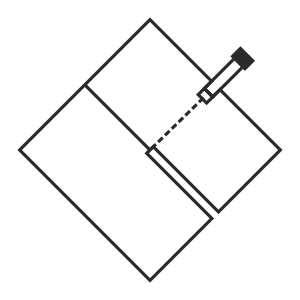

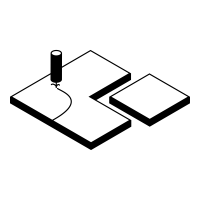

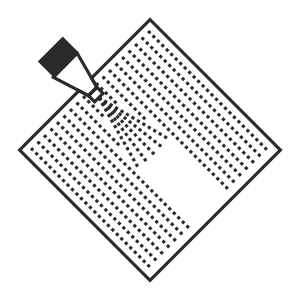

Сучасна система вимірювання, заснована на принципі лазерного сканування LaserQC, дозволяє швидко, точно та автоматично перевіряти будь-які плоскі зразки деталей.

Розроблена спеціально для потреб виробництва виробів з листового металу, система LaserQC скорочує час перевірки зразків до кількох секунд, значно спрощує процес реверсивного проєктування, підвищує ефективність та мінімізує помилки.

Переваги LaserQC:

> Автоматичне калібрування

> Швидке формування результатів вимірювань і аналіз якості виготовлених деталей> LaserQC має функцію реверсивного проєктування, яка дозволяє створювати креслення на основі існуючої деталі за результатами сканування

> Система зберігає дані у файлах, сумісних із кресленнями CAD. Якщо відсутнє креслення або DXF-файл для конкретного виробу, LaserQC легко створить його

> LaserQC перетворює складні логотипи, етикетки, написи, цифри та контури дизайну у DXF-файли для виготовлення на лазерних, плазмових, гідроабразивних верстатах з ЧПУ або на штампувальних пресах

Точність лазера: Безконтактне сканування забезпечує точність вимірювань ±0.05 мм при 2D-скануванні

Робоча зона сканування: до 1200 x 1200 мм

Ціна: 1 скан — від 300 грн без ПДВ

Якщо потрібна доробка моделі — 1 година роботи конструктора від 500 грн без ПДВ

Телефон конструкторського відділу: +38 097 700 25 40

Принцип роботи та відеодемонстрація: